Laminated labels

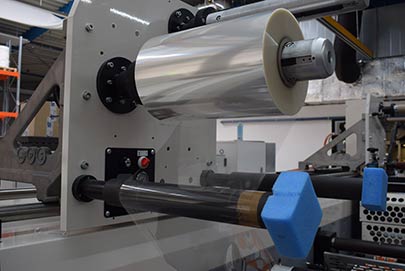

Laminated labels are a popular choice for companies that value long-lasting and aesthetically pleasing labels. With this method, a thin layer of foil is applied to the label, resulting in increased resistance and a brilliant shine. In this article, you will learn why foil-laminated labels can be an excellent choice for your business and what to consider when choosing.

Durability and aesthetic effect in one

Labels are exposed to a variety of environmental influences, such as moisture, abrasion and light. With foil lamination, you can ensure that your labels are resistant to these influences and therefore last longer. The foil forms an additional protective layer that protects the label from damage and thus maintains legibility and aesthetics.

In addition to longevity, the foil lamination also ensures an aesthetically pleasing effect. The glossy surface of the film gives the label a professional and high-quality look. Especially for labels for premium products or brands, foil lamination is an excellent choice to professionally present the product.

There are various options when choosing foil lamination, which may vary depending on the intended use and design of the label. The choice of foil type also depends on which inks are used, as not all foils are suitable for all colours. Glossy foil lamination is best suited for colourful and contrasting designs. On the other hand, a matt foil lamination provides a subtle and elegant look.

With the so-called “soft touch” foil lamination, a very soft grip experience can also be applied for the consumer. Graphic designers and marketing agencies in particular like to experiment with this haptic experience. The cost compared to a varnish is only slightly higher.

Summary

Labels with foil lamination offer a variety of advantages that affect both durability and aesthetic effect. The film forms an additional protective layer that protects the label from environmental influences and thus maintains legibility and aesthetics. In addition, the glossy surface of the film gives the label a professional and high-quality look. When choosing foil lamination, various factors should be taken into account to ensure that the label serves the desired purpose and is visually appealing. Contact us and we will be happy to advise you and make you an individual offer.