Ecology

We protect the environment!

Without a change in lifestyle in all areas, the major environmental problems cannot be solved in the industrial nations. Every economic entity, whether individual person or group, consumer or producer, small or large enterprise has to face this problem. Proactive measures are required! It is no longer sufficient to just wait for more and more and sometimes contradictory new regulations that force you to act.

For this reason, Froben Druck has been pursuing the idea of making label production more environmentally friendly and sustainable for a very long time. Every change in the production process and every new or replacement investment takes into account ecological aspects. Financial considerations are not the sole basis of decisions. Our company headquarters is still located in the center of Ottersberg, emissions are avoided and construction designs are adapted to the townscape.

With us, all production stages are considered separately and are constantly optimized. Back in 2010, we switched from solvent-based printing plates to the more eco-friendly, water-washable flexo plates in flexographic printing. This was a real challenge at the beginning when it came to maintaining our high print quality. Furthermore, the consistent switch to low-migration colours was implemented early, as this was still sneered at by many because of high costs and technical difficulties.

Constant new investments in modern printing machinery and peripherals ensure optimal production. Compared to the older machine generations, the newer systems use less raw material and energy.

Of course, our employees represent an important potential. Thinking along and critically following the process steps as well as carefully handling all resources are a matter of course. Our employees are encouraged and trained to use as few chemicals as possible and to replace aggressive substances with less damaging substances. Special cleaning equipment, e.g. for cleaning anilox rollers and paint pans not only results in healthier working conditions but also reduces the overall use of chemicals.

We also incorporated this concept into our building. The printing presses are connected to a heat recovery, so that inevitable waste heat can be used again for space heating. The lighting has also been completely converted to economical LED technology.

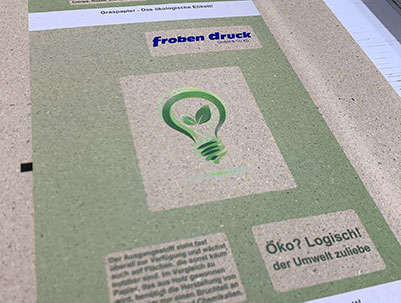

In addition to the technical possibilities in production, we also place great emphasis on the sustainability of the raw materials we process. By now, the entire standard range of adhesive paper is FSC®-certified (Forest Stewardship Council). Alternatively, PEFC-certified material is used as well. The most ecological adhesive paper is currently made from grass paper. Of course, we also included this in our product range.

With us you can be sure that we will never use more CO2 than necessary for the production of your labels. We gladly invite you to our headquarters to convince yourself of the advantages.