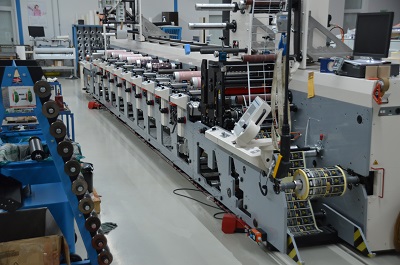

Flexographic labels

Flexographic printing is a very common printing process for labels, as it offers high productivity and a wide variety of possibilities in the finishing of labels. This process is particularly suitable for large runs and spot colors, as it enables a very high printing speed.

The technology of flexographic printing is relatively simple. It is a high-pressure process in which the printing plate is made of rubber or flexible plastics. The printing plate has raised spots that transfer color directly on the substrate. Printing is carried out by anilox rollers, which ensure uniform ink absorption and transmission.

Advantages of flexographic labels

Flexographic printing is a fully rotary process in which the printing plate is continuously rolled up on a printing cylinder that rotates at high speed. This technique allows many finishing options to be applied to labels in flexographic printing, including cold foil stamping and backside printing. In cold foil embossing, a thin metal film is applied to the label to give it a metallic surface. Backside printing allows information to be applied to the back of the label.

In addition, flexographic labels are very flexible in processing various materials, including paper, foils and cardboard. This makes the process suitable for labels that are used in difficult environments, such as chemical products, food and beverages.

Another improvement in flexographic printing is the use of high-resolution cameras that scan labels for defects during production, ensuring optimum quality. Due to the high printing speed, a control without technical support can hardly be guaranteed. Due to the use of high-quality anilox rollers and the avoidance of crushing edges, the resolution in flexographic printing today is very high and offers exact color control.

Flexographic printing is a very powerful printing process that is used for labels in many different industries. We have state-of-the-art machinery and experienced staff to ensure high quality. Production is very economical because set-up times are short and production is fast. If you would like to have labels produced using flexographic printing, we are at your disposal and meet your requirements.